This news item was published more than six months ago and may no longer be relevant.

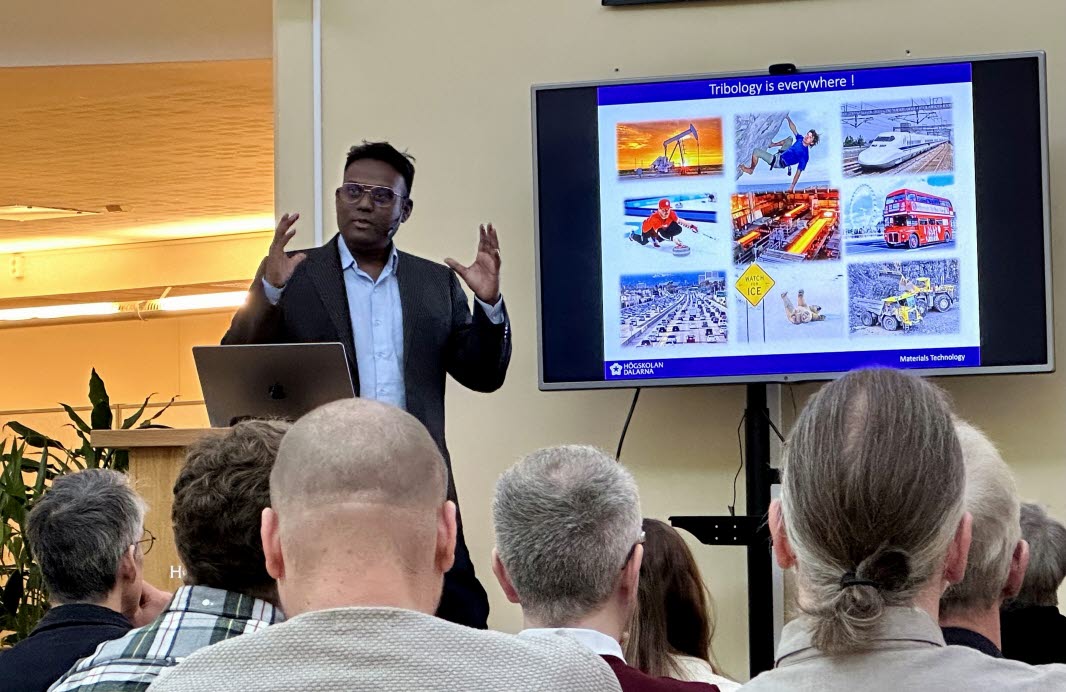

Tribology is the science and technology of interacting surfaces in relative motion, and the key elements are friction, lubrication, and wear. A classical example of friction and wear in a wind turbine gear assembly was shown. For a researcher, investigating the worn surface under a microscope provides clues to control friction and wear. Corrosion is the degradation of materials because of its interaction with the environment and it can be considered a disease for metallic materials. There are different forms of corrosion, and one type is Tribo-Corrosion. It is estimated that it costs around 2.5 trillion US dollars to deal with corrosion. Thus, researching in the field of tribology and corrosion directly promotes energy efficiency, resource conservation, and sustainability.

During the presentation, results from a research project related to rock drilling tool bits made up of cemented carbides (tungsten carbide-cobalt, WC-Co and tungsten carbide-nickel, WC-Ni) were shown. By understanding the change in microstructure, the role of nickel, Ni, is promising for both wear and corrosion resistance properties and could be a better choice to replace cobalt, Co, which creates health hazards while manufacturing the product.

Further, four current research projects involving steel and titanium alloys were briefly described, some of which were shown during the afternoon’s poster presentations. The research projects at Materials Technology directly contribute to the Sustainable Development Goals (SDGs 3, 9, 12, 13, and 17).